In Saint Renan, Finistère, the Le Jeune Hospital chose Burlodge for an innovative equipment solution to distribute meals within its medical and residential facilities. The Burlodge equipment are motorised and their systems Wi-Fi connected. Meals are served on plates or in multi-portion trays, in bedrooms or dining rooms. Patients, residents and employees alike have rediscovered the pleasure of a good meal. By Marc Ozias

“It started from scratch,” explains Joris Theuriet, the North West regional sales director for Burlodge France. His client had a challenge. They wanted a solution for plated and multi-portion service using Cook-Chill with approved, ergonomic and motorised equipment. “We started from a long way off,” admits Marie-Hélène Larose, head of purchasing and logistics at the Le Jeune Hospital. Here, two high dependency care homes for the elderly take care of 82 and 92 people respectfully with a service at midday in the dining room and in the bedrooms for supper. A geriatric re-education centre also serves meals for 40 patients on trays. In addition, congregate dining is provided as part of therapy sessions. “Caring is at the centre of our strategy for improving the quality of our hotel service to maintain people’s autonomy. Each meal must be a privileged moment. In the past, some of our residents complained that the food was cold and the service personnel noted a high increase in musculoskeletal disorders. We had to acknowledge that our bain-marie trolleys, dating back as far as 2006, no longer met regulatory requirements”, she states. An internal audit on all the stages of the catering process convinced the senior leaders of the Hospital to invest in new equipment. In compliance with procurement policy, the hospital called on the four major manufacturers of food distribution equipment in France. It was Burlodge that won the department’s tender perhaps with a little help from some raving fans at other hospitals. “Of our own accord, we visited the high dependency care home for the elderly at Saint-Vincent Lannouchen Saint-Jacques at Landivisiau where the Burlodge products were already used”, relates Marie-Hélène Larose.

A Genuine Quality Service

For Burlodge, there were three main concerns that the hospital wanted addressed. First, to supply an equipment system able to serve multi-portion meals and to reheat thirty-two plates per cart.

Second, the system must satisfy the food safety requirements of Cook-Chill preparation. The third requirement was to have a motorised trolley which had to offer a higher level of comfort at work and limit musculoskeletal strain.

In the end, ten carts were ordered by the hospital from Burlodge. “Throughout the process, we were accompanied by Burlodge”, the purchasing manager confirms. Together, Burlodge and the Food Service Staff completely re-organised the operational process to ensure a higher quality of service.

“Staff value offering a more hospitable meal service, more akin to an actual restaurant.”

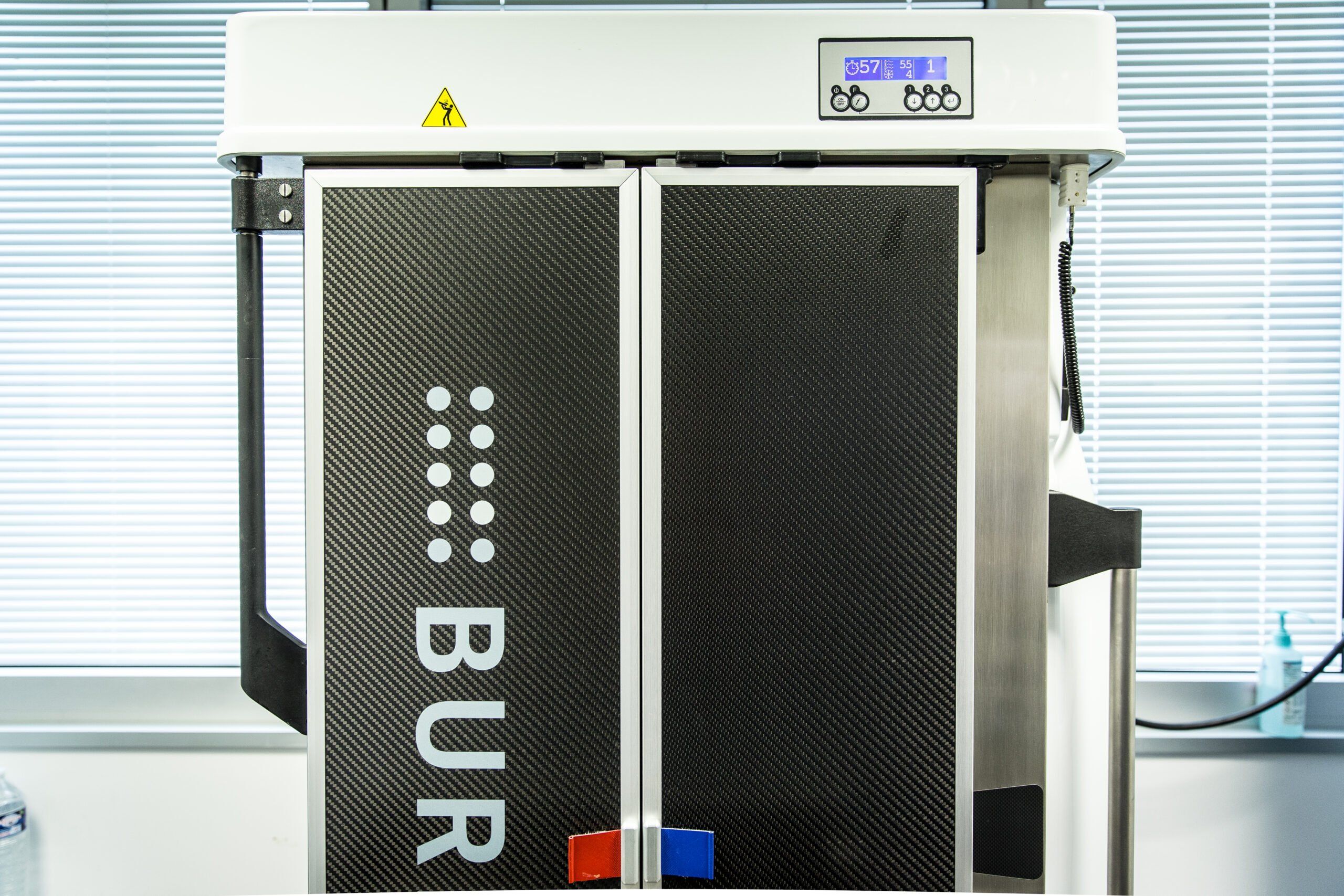

Over 6 months of research and trials were carried out in order to refine an equipment prototype which met all the needs of the project. Burlodge found a right-sized melamine plate from Spain that supported high heat reheating. These plates enabled four plates to be arranged per level, over the eight shelves of the “Multigen 105” trolley, Burlodge’s flagship product, which guarantees reheating in 50 minutes. For hot preparations, thirty- two plates can be transported, and can be adapted to different diets. Correspondingly, the same number of meal plates can be accommodated in the cold section (appetizers, desserts, and cheeses). GN pans/containers can just as well be used for a maximum of forty portions.

Competitors were tantalised

The biggest challenge for Burlodge France was the need to include motorisation on the carts. Up until then Burlodge had not deployed this concept to the Multigen range of equipment and the idea was almost non-existent in the sector. “Here again, we contacted and tried many of the motorization manufacturers and we found a model operated by a control handle”, explained Joris Theuriet. This technical solution proved to be more than satisfactory. An unexpected consequence after the deployment of the fleet of carts (two in medicine, one in addiction studies, and the seven others in the two high dependency care homes for the elderly) saw competitors come to take a closer look at this innovation at the hospital. “Motorisation is a big plus!”, says Marie-Hélène Larose proudly. “After the initial fears passed, our dedicated catering service teams keenly learned to appreciate the manoeuvrability, the easy-clean aspect and the overall comfort of the trolley. And, that applies to all generations”, she states. “I even saw an employee, two weeks from retirement, who insisted on using it before leaving.”

Benefits on all levels

“For us, it is a radical change. We have evolved from collective distribution to individualised catering”, says Marie-Hélène Larose. “Touring various establishments convinced us of the choice of air convected meal reheating technology, rather than thermo-contact

“Mealtime is really important for a resident or patient. Today, we estimate that it plays a 50% role in their recovery and their morale.”

Admittedly, the convected air means that we had to rethink preparations such as sauces, cornmeal or potatoes, which constitute “a staple food” in Brittany.” “It’s revolutionary”, enthuses the head of purchasing and logistics, whose expert eye particularly appreciates the manufacturing quality (stainless steel, welding) and the finish of the equipment. Additionally, the “Multigen” trolleys are Wi-Fi connected. They allow transmission in real time of information relative to the start of cycles and the reheating of the meals. The data is centralised, and can be consulted and edited using a simple and intuitive control panel. Food probes can be connected to the cart software system and are used to take the inside temperature of food, in order to improve HACCP monitoring. “We have not yet calculated precisely but, at all levels, we have made very significant savings”, confirms Marie-Hélène Larose.