University Health Network – Toronto (UHN) recently welcomed a much-needed upgrade to its food delivery system. The result is extremely positive, reports Susan Grove, RD, MBA, Senior Director of Nutrition and Business Operations, who has been in her current role since 2004 and at UHN for 33 years. The positive transformation has resulted in a higher level of food safety and operational efficiency. Patient and staff comments have been extremely positive noting the improvements

in the appearance of the meal tray and temperature of the food. The sites involved in the recent transformation include Toronto General Hospital, Toronto Western Hospital, and Princess Margaret Cancer Centre. Two Toronto Rehabilitation Institute sites, University Center and Bickle Campus, implemented Burlodge’s B-Pod tray system in 2011. The Princess Margaret Lodge for cancer patients converted to the system in 2013.

In 1994, UHN took measures to contain costs by moving away from a scratch food preparation system to a cold-plating system nicknamed a “kitchenless” system. “With this preparation style, patient trays were assembled with ready-to-serve frozen and fresh foods and placed in carts that were insulated but had no onboard refrigeration or temperature monitoring and transferred to nutrition centers on the [patient] floors,” Grove says. At the centres, staff moved items that needed heating into a retherm oven and, once hot, placed them back onto the trays in the cart. Coffee and tea were made and put onto the trays at the last moment before service.

“The system was at the end of its useful life and there was concern about how much longer the system could perform adequately to ensure food safety,” says David Teixeira, Principal, Kaizen Foodservice Planning & Design Inc. He and his firm’s team helped plan and design the new food delivery system. “The situation created an opportunity for UHN to realign the decentralized retherm locations to provide better access and response to patient needs and maximize staffing efficiencies,” he says.

In July 2016, UHN adopted the Burlodge B-Pod tray delivery and rethermalization system at the last three of its seven sites. “We adopted this system because a consultant’s operational review indicated that a food cart delivery model was still the most cost effective for our operation as compared to the more expensive spoken menu and room service systems,” Grove says.

“Cost-effectiveness is a big driver for us and we continually strive to achieve a cost-leadership position.”

Another driver was bringing consistency across the UHN network.

“When we merged with the Toronto Rehabilitation Institute in 2011, a year later, those facilities went with the Burlodge system, so we were on two different systems,” Grove says. “Burlodge is a convection system, and our old system was conduction. It was very difficult to purchase products that worked for both. We wanted the same cart system across [UHN] that would facilitate more flexibility and higher quality with regard to the menu.”

The Tray Assembly and Delivery Process

At Toronto General Hospital, site of the main/central kitchen, patients receive a meal preference sheet from Nutrition Services upon admission to determine their food and beverage likes and dislikes. Staff input preferences into the computer’s food and nutrition services software. The software system creates a personalized meal ticket for each meal for each patient, which is used to assemble the patient meal in the central kitchen. The same menu preference process is in place at Toronto Western Hospital and Toronto Rehab Bickle Centre and University Center. In contrast, many patients at Princess Margaret Cancer Centre make selections from a printed menu each day. At Princess Margaret Lodge, all clients are outpatients and select between two main menu choices.

In Toronto General’s kitchen, staff members on the tray assembly line receive the computer-generated meal tickets and begin tray assembly one meal ahead of delivery because meals are not only served on-site to Toronto General patients but are also sent to the other sites. For example, at 7 a.m., staff produce lunch trays for that day; just after lunch, they assemble dinner trays; and after dinner, they assemble breakfast trays for the following day.

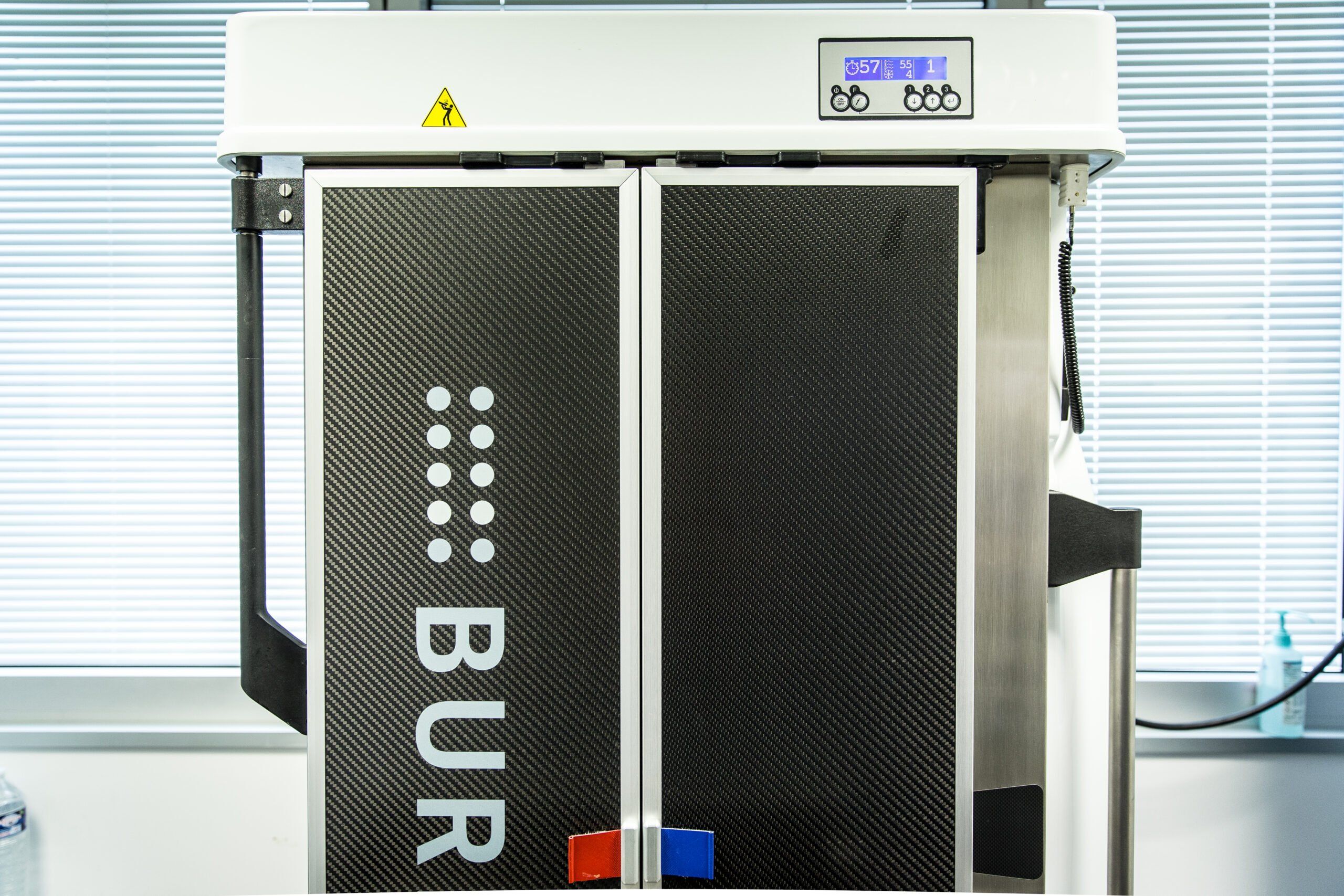

Staff assemble trays by placing cold foods that will remain cold on one side of the tray, while cold foods that will be heated before service to patients are placed on the other side. Trays are sent down a conveyor belt to the end of the tray assembly line, where a staff member checks for fulfillment accuracy and loads the trays into a Burlodge insulated tray carrier called a Pod that can hold up to 20 trays.

Staff transport the Pod full of trays to a nutrition center at Toronto General and into refrigerated trucks that will transport Pods to the other two hospital sites. Once the Pod has reached the nutrition center, it nests underneath a retherm station called a Base Station, which will keep everything cold until the hot food is heated up on the trays.

“The advantages of the B-Pod’s integrated technology gives Susan and her managers throughout UHN advantages like never before,” says Thomas Holzschuher, Vice President, Customer Solutions for Burlodge. Built-in HACCP monitoring ensures food quality and safety, while networking through a LAN or Wi-Fi connection means operators can interact with their fleet of equipment in real time using a centralized PC at each site.

On the B-Pod Base Station, the LCD Control Centre gives staff fingertip functionality with three-cycle touch pads, a countdown timer with temperatures, an audible alarm and an automatic cycle timer for seasonal changes.

“The cart’s HACCP monitoring system enables food temperature probing to ensure the correct internal food temperatures prior to service. ” Grove says. “We can also monitor carts from each site’s central computer, so we can always be aware of the air temperature of the Pod’s internal cavity.”

The B-Pod’s unique manipulation-free nesting system allows the Pod to reside within the Base Station to effectively create a one-piece system. This approach eliminates the need for opening and closing of doors, as well as docking and inserting removable racks. With Base Stations mounted to the floor and the ability to fit the Base Stations back-to-back, the B-Pod promotes a more efficient use of space for easier workflow.

Once nested and in accordance with the preprogrammed timing, the Base Station will begin heating one side of the tray while the other side remains chilled. When ready, an audible alarm indicates the Pod can be de-nested, and trays can then be presented to patients.

Staff members pick up trays, place them back in the delivery carts and return them to the kitchen, where they are washed and sanitized for the next cycle of service. Soiled trays from the two other sites (Toronto Western and Princess Margaret Cancer Center) are brought back to Toronto General for cleaning and sanitizing.

Finding Space for the Carts and the Remote Cooling System

“Because there are plans for future bed growth at some sites, we needed more carts than previously, so we had to find space for and construct new nutrition centers at all three hospital sites,” Grove says. “In addition, we needed space to install Burlodge’s remote cooling system, which is hooked up to a large compressor at each site, to save energy costs.”

In order for the new tray delivery system project to be successful, the nutrition services staff had to embrace the new work spaces. “The staff had been using retherm equipment without onboard refrigeration for over 15 years, so we were concerned that introducing new equipment with onboard compressors on each Base Station would raise concern with staff due to the sounds of compressors running,” Teixeira says. “We were also aware that the concentration of numerous retherm stations with self-contained refrigeration systems could result in the need for an upgrade to the air makeup system within the space. So we worked with refrigeration solution experts and Burlodge to design a sophisticated remote refrigeration rack system to reduce heat and noise.”

Thomas Holzschuher was the project manager at Burlodge responsible for the UHN project. “The use of remote compressors established UHN as a pioneer in Canada. We had installed remote refrigeration systems in the USA before and some water-cooled systems in Canada, but a remote refrigeration system was a new concept for Canadian healthcare foodservice,” he says.

Grove is extremely pleased with the results of the new food delivery system. She knows the system provides for safer food because food stays at proper temperatures throughout the process. “We were waiting for change for a few years,” she says. “We’re very happy with how this sys-tem is working for us now. We have one consistent system that is cost- effective and facilitates achieving a cost leadership position, ensures food is prepared safely, and provides us with flexibility throughout our network.

“You can always count on Burlodge to approach every project with great enthusiasm and a determination to succeed,” says Burlodge President Paul Gauntley. “We look at our work with UHN as a fruitful relationship that will only grow stronger in years to come. Together, we work.”