If ever there were a saying that at once frustrates and motivates innovators, “That’s how we’ve always done it” would be it. It presumes change is unnecessary and questioning established norms futile. It says “I give up” without giving anything.

Take that as a jumping-off point for how Burlodge’s B-Lean system established itself in 2008 as an alternative tray assembly equipment system for healthcare foodservice. This small, highly adaptable assembly process/pod system provided an answer for space-challenged operations looking for improved performance.

The B-Lean system uses a flexible work cell design that can be quickly configured into a variety of formats. Customization gives users the liberty to arrange workflows based on the particular needs of each meal each day.

B-Lean has helped healthcare foodservice operators reimagine traditional tray assembly. It also brought lean manufacturing principles to healthcare food operations. While hardware can significantly transform operations, B-Lean’s enduring legacy may be how this thinking continues to improve performance.

A Lean Primer

Lean as a concept became widely known during the ’80s and ’90s. It advocates eliminating waste in terms of time, inventory and flow, and it intends to bring greater value and efficiency to production. For foodservice operations that work under relentless time constraints, its ideals are a natural fit.

For Burlodge, B-Lean thinking extends beyond the adaptable, compact and ergonomic design of the equipment to something more comprehensive. It includes streamlining menus, organizing inventory and boosting the efficiency of operations. Lean thinking strongly aligns with how Burlodge has always advanced ideas of continuous improvement with equipment and processes.

The Trouble with Traylines

Paul Gauntley, President of Burlodge Canada & USA, says the B-Lean system emerged in response to the aggravation of outmoded traylines. In the early 2000s, the company conducted a study of these systems, which revealed inefficiencies everywhere. The main issue was wasted time.

Task duration along traylines tends to vary. Some tasks take five seconds, others 15. This means an inordinate amount of waiting for some staff, and those times add up. Burlodge’s study found that for a tray that required 100 seconds to complete, 55 seconds was spent on activities that added no value.

The poor ergonomics of beltlines also proved problematic. Unnecessary reaching, crouching and bending meant that repetitive strain disorders were commonplace. Minimizing movement, improving the natural flow of production and making the workable space easier on staff was essential to the solution.

First Impressions

It was Burlodge’s work with a longtime client that first revealed the effectiveness of lean thinking. Phase one of developing B-Lean reduced the time of tray completion times by 35% while phase two sharpened the focus on improving ergonomics.

“We originally referred to B-Lean as ‘bent metal,’” says Gauntley. “This was simply a structure on wheels. No mechanics or compressors, but a different approach all the same. As time went on, we started to understand the importance of refrigeration.”

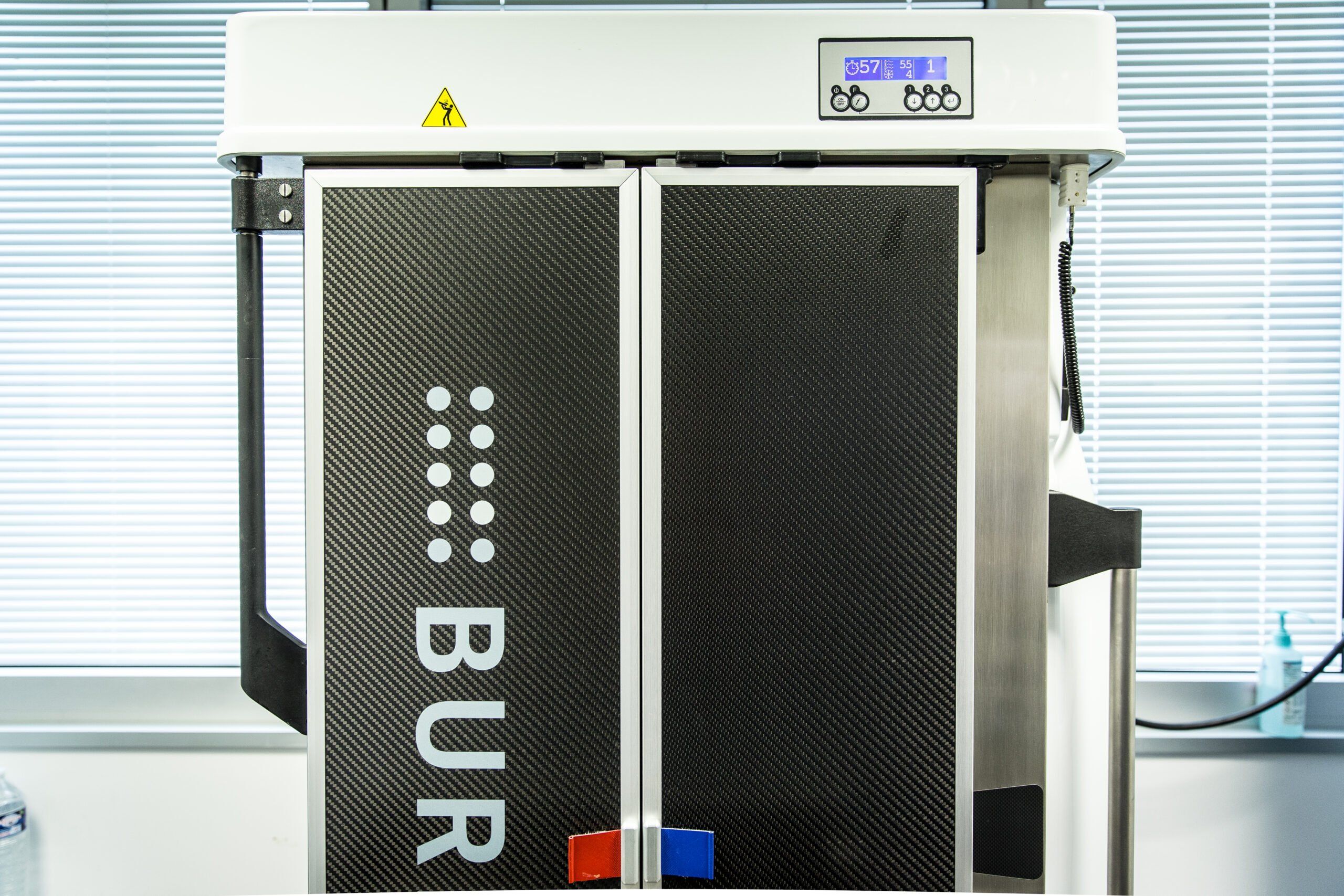

That’s when Burlodge revamped some 20-year-old equipment and created a mobile, double-door refrigerator with gravity-fed shelving. Though demand for the product grew, the availability of used equipment dwindled. The idea stuck, however, and a new refrigerated component for the system was created and called B-Cool.

Bring on the Victory

This led to a unique collaboration between Burlodge and Victory Refrigeration, two companies operating under the Ali Group banner.

The connection with Victory helped to accelerate the development of B-Cool equipment, starting with air curtain technology, a system that circulated a consistent stream of cool air across the B-Cool’s door opening.

Matt Kampert, Vice President of Manufacturing, Ali Group North America – Refrigeration Division, found himself on the leading edge of this effort. He visited different Burlodge client sites to see the equipment in use — an eye-opening exercise that helped him better direct his engineers.

The shared knowledge was beneficial to both operations. Victory’s engineering helped to refine the details of B-Cool’s functionality and performance while Burlodge’s extensive client network provided feedback to generate the hands-on need for those improvements.

Oscar Villa, President, Ali Group North America – Refrigeration Division, says, “Burlodge challenged us to improve our product and we made it better by enhancing the performance and ergonomics.” He also points out that the unexpected benefit of the collaboration has helped Victory refine other products.

“At the end of the day, the user drives the demand”

The Idea Evolves

Gauntley recalls how a number of different iterations followed that initial collaboration. After the air curtain, the development team placed a door on the back of the unit for uninterrupted restocking

of goods, which resulted in the B-Cool Double Door Air Curtain. From there, lean thinking shortened the height of the server-side door and introduced interior gravity shelves, which became the B-Cool Lean.

“No matter how good the product is, there are aspects that the end users evaluate and that we won’t think of sitting at a desk,” says Villa. “At the end of the day, the user drives the demand.”

The B-Cool family of equipment joined the other specialized equipment in the efficient B-Lean system. From the Burlodge team’s perspective, the end user needed to understand the thinking that drives the

B-Lean approach.

Leaning into the Operation

“We realized lean wasn’t useful if the staff weren’t educated,” says Gauntley.

Burlodge took clients to other facilities for a firsthand look. They set up dummy lines for practice and introduced small groups of frontline staff to the system. Staff could ask questions of on-site Burlodge personnel, pose problems, explore solutions and even help make decisions about the production workflow.

“As soon as someone expressed interest, a full-blown cascade of analysis and assessments follows,” says Gauntley.

That included menu reviews, site assessments, planning, equipment needs, staff job descriptions, rotations, metric planning and much more. The effort to invoke a lean mindset helped clients better appreciate the impact of the proposed improvements.

A series of testimonials let the Burlodge team know they were on the right track.

As one healthcare foodservice manager noted, “I can’t emphasize enough the importance of engaging staff from the outset. People resist change and you can’t fast track this sort of thing. Give the staff the time to do it. Invest in it.”

A director of foodservice operations said, “These are the people who are using it day-to-day. We let them play with the equipment from early on and decide how best to arrange it.”

B-Lean customers also stressed that engaging employees with the new system early on improved team dynamics in addition to workflow.

Ease of Movement and Adaptability

Ergonomics also had an immediate impact. One testimonial appreciated the fact the B-Lean system can be reorganized to accommodate peoples’ heights and arm lengths. Further, with its angled arrangement, gravity shelves place items within easy reach and maintain natural body movement so there is no need to strain.

Paul Sico, EVP, Sales and Marketing for Burlodge USA, believes one of the most persuasive points revolves around B-Lean’s adaptability.

“I think clients respond to the fact that it can fit into any operational model, from cold plating, hot plating — whether hot line or room service — or even a hybrid model,” he says. “Whether layouts are centralized or decentralized, the system can change with the operational model, staffing and even the facility.”

Staff Support and Patient Satisfaction

Another foodservice director said that her operation had been assessing more flexible assembly stations, both for the diverse patient needs as well as a self-paced system that would accommodate staff. She noted that many of her staff who have English as a second language had time to read the tray ticket and ensure accuracy. “The staff find it much easier,” she noted. “We have three traylines and we do 700 trays per meal in 90 minutes. Our numbers meet the staff minutes-per-tray standard, they’re accurate and it’s easy to clean.”

Operators agree that staffing numbers don’t necessarily change, but resources are better used and reallocated in some cases. In most cases, a person is assigned as a floater who restocks and feeds the items, while handling any late changes to trays.

Another client noted, “If you have 15 people on a trayline, you can definitely have reductions with B-Lean.” She also said that lean thinking has led to reassessing operational priorities. “I think it focuses you on what is driving patient satisfaction. You may have too many things on your menu and this is definitely an opportunity to simplify things.”

“I think the breakthrough moment is when clients understand the lean principles and the cost savings that can result,” Sico says.

Look Forward, Lean Ahead

Naturally, the improvements to the B-Lean system are ongoing. It’s an inherent part of the system’s mandate, whether it comes from Burlodge staff, Victory engineers or suggestions from clients who work with it every day.

Currently, over 120 installations are in operation and a tide of foodservice operators are now abandoning the ways they’d always done it in favor of a lean operation.