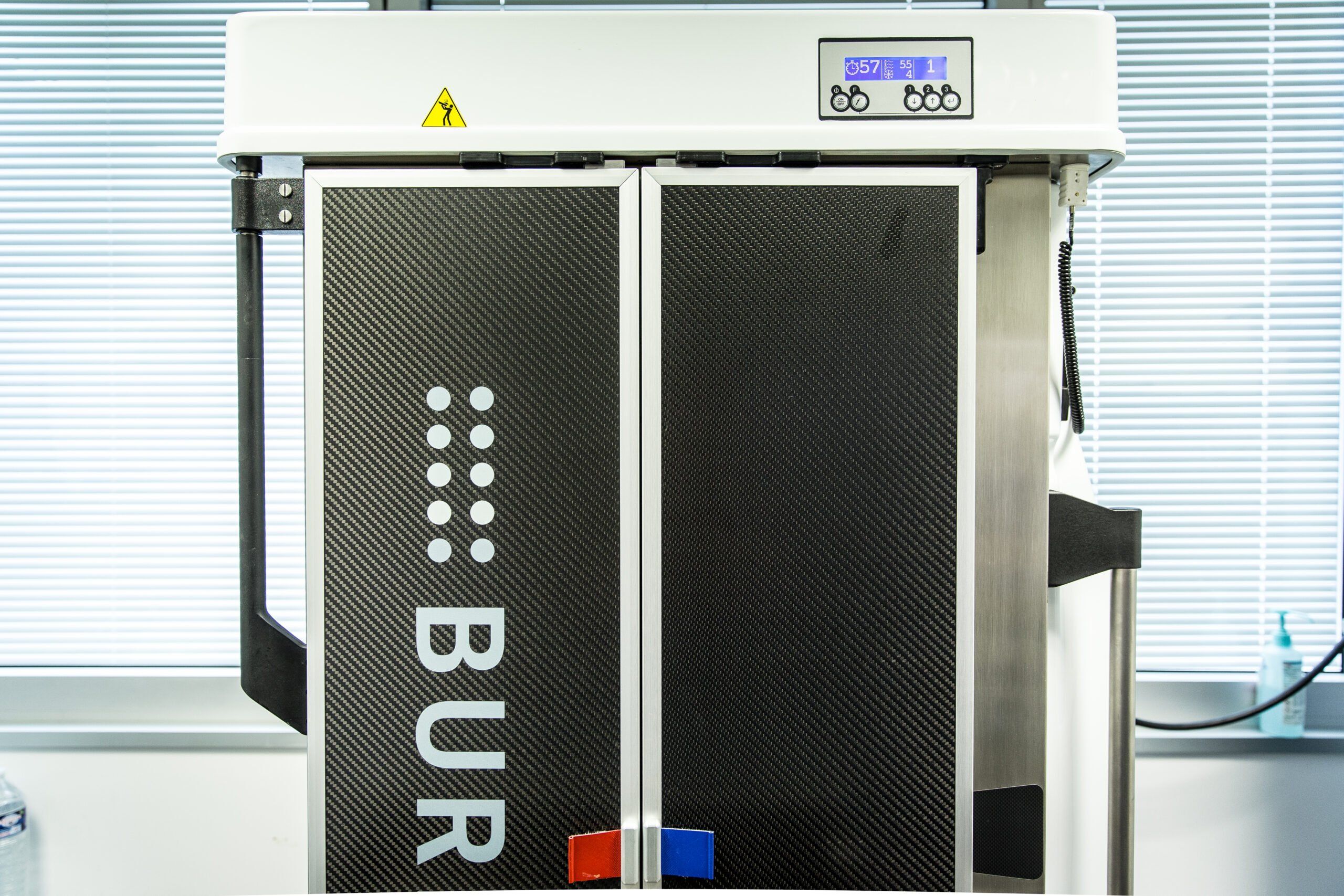

When it comes to discussing the benefits of a B-Lean system, there are many moving parts. Literally so, in fact, given B-Lean’s pod-based meal assembly system design. Don’t fret – I’m not going down the rabbit hole of talking equipment or engineering. Instead, I want to highlight one of the key advantages of the B-Lean system that most food managers overlook when assessing their options. Specifically, the human element.

Recently, as I was taking part in a story about the evolution of Burlodge’s B-Lean system, a number of food service directors detailed how B-Lean had revolutionized the way they assembled meals. I’ll share the story when it comes out (it’ll appear in an Ali Group publication in a few months), but the one overriding theme was how our approach had genuinely engaged frontline staff as never before.

The Lean Philosophy

Chalk that up to the Lean philosophy that has helped drive the equipment and system design.

For those unfamiliar with it, Lean thinking revolves around eliminating waste in key parts of an operation, and specifically focus on time, inventory and flow. Further to that, Lean emphasizes a bottom-up approach – such as involving frontline staff. It maintains that top- down thinking will only take an organization so far. To include the people who work directly with the equipment every day you’ll get a clear notion of what works best (and what doesn’t).

That hinges on whether there is an opportunity to voice those ideas – if there’s room for them to be conveyed or if those overseeing an operation are receptive. Let me assure you, it pays in so many ways to listen and then act. What you give up in control you regain in staff buy-in and stronger team dynamics.

Keep it Real. Make it Active.

That’s why we’ve not just invested in Lean training for many of our staff at Burlodge, but when we’re implementing a new system for a client, we reserve ample time in advance to promote Lean thinking through hands-on activities. We tour clients through operations so they can see how it’s used and then set up practice rooms where staff can interact with the equipment, explore different arrangements, discuss pros-and-cons and so on.

“I can’t emphasize enough the importance of engaging staff from the outset,” advises one food director. “Their opinions are valued.”

Another mentions, “These are the people who are using it day-to-day. We let them play with the equipment from early on and decide how best to arrange it.”

When They’re Involved, They’re Invested

Because B-Lean is meant to adapt to whatever the physical parameters dictate, it gives people the liberty to explore different configurations. To see that in action is incredibly revealing. People are far more invested in making the system work when they have contributed to the solution. Compare that to a traditional beltline where someone is assigned the same task, day-after-day. Can you even question the issue of motivation when faced with that?

There is always going to be someone who will be reluctant to comply. Detractors can be very influential on other staff. That’s why the simple act of relinquishing some control and opening the floor to consensus decision making can work wonders.

As one of our clients sums up, “This has made all the difference in the adoption of the B- Lean and the quick uptake.”

Working with staff prior to implementation has certainly proven to be one of the more gratifying activities I’ve encountered. We see teams really come together to work through the challenges of improving systems. This strengthens the operation from the core, which is essential to improving efficiencies, tray accuracy and budgets. I’d say that kind of proposition is always worth closer consideration.