Angelo Speranza is CEO of Burlodge and temp-rite, brands that specialize in meal delivery systems and equipment for the healthcare, long-term care, prison and educational sectors. He shares insights and stories from his journey so far and why the customer must always remain central to everything

Burlodge started in 1984 when my father, Bruno Speranza, who was in the process of setting up his own company to sell foodservice equipment, asked me if I wanted to work with him. This was a complete shock because working with your father is never easy. It wasn’t what I was planning, but it turned out to be the best decision I ever made. At the time he was managing director of Zanussi UK and I was completing my business studies and intending to take a sabbatical year. How that changed in an instant.

My father was a great role model and mentor– not just for me but to many of our colleagues.

I was very grateful for the opportunity and, understandably, it was an exciting time. I will never forget those early days working from our dining room table.

Shortly into our efforts we were approached by a healthcare equipment supplier who wanted us to distribute their products in the UK. We accepted and quickly became well established in the market, but those early successes were dashed when our supplier was being acquired and demanded direct access to the UK market. Sadly, they broke contractual obligations and litigation followed.

It was a major frustration because we’d just started to realize the fruits of our labor. We had the know-how, market knowledge and drive, but we had no product. The second chapter of Burlodge began.

Burlodge takes root

We began designing and developing our own product, and within 12 months, we introduced our first meal trolley. It made waves in the market, and we proceeded to win a majority of projects.

Soon enough we started to distribute our products in Italy before venturing to Canada, where the food distribution methods were similar to the UK NHS model.

The US and France followed. We had a clear plan to enter one market at a time and do that well before moving into a new territory, either directly or via key distributors and partners.

By 1998, we had been approached by the Ali Group and we agreed to become part of its group of companies. After that, we started to work with Ali Group companies Metos, Stierlen and Moffat and subsequently temp-rite once it was acquired by the Ali Group. Together with our teams, partners and products, we strive every day to be the best in the industry.

The power of the collective

Ali Group is unique. We all operate as individual companies in our own market segments, but the power of our collective specialties and talents gives clients tangible benefits. Sharing know-how, market knowledge and supplier connections – these are benefits we offer that our competitors lack.

Add to that the intangible advantages, such as peace of mind for clients who are making major investments in meal delivery systems. It’s incredibly reassuring for them to buy from a stable, profitable company – backed by an international group of Ali’s caliber. What’s more, the Ali Group culture blends the family business feel on one side within a strong corporate structure, so we attract excellent talent.

Taking the lead

I was appointed CEO 10 years ago when my father Bruno retired. He’d made such an impression during his time and people still ask after him. Those aspirations and ambitions my father and I started with are still in our DNA. I think people really sense the passion that we had for the business – that

we really took comfort in knowing we made a difference to patients who were dining in a difficult and unfamiliar environment.

We always focused on bringing some dignity to the patient experience. I still get as much joy thinking about facilitating well-presented meals to people around the world as I believe it does to those enjoying those moments.

At Burlodge and temp-rite, we have three simple rules: take care of every customer’s needs, develop products that make a difference, and, employ the most skilled and professional team. In that, we have developed a multi-talented team that includes chefs, dieticians and engineers who, together, give us a better understanding of customers’ needs and challenges.

Still, we don’t like to make claims like, ‘we innovate’ or ‘we’re the leaders in…’, as this marketing-speak means little for most people. We prefer to focus squarely on our customers’ needs. We pride ourselves on speaking the same language because with our experience we understand what being on the front line really means. That gives us the insights necessary to develop the solutions and systems that have become the industry standard.

I can confidently say that if you cite 10 major developments in our industry over the past 20 years, we’ve developed the majority of them.

Much more than a tag line

If there’s a claim that we’re comfortable standing behind, it’s our motto: Together, We Work. On

the one hand, it speaks to the effort we invest in getting those systems and solutions right. At the same time, it acknowledges the importance of that process being a collaboration between Burlodge and its clients as well as Burlodge and its partners. It defines our approach and distinguishes our final product.

The result is that we’ve produced one of the widest product ranges on the market and we’re prepared to tailor solutions precisely to customer need. The sheer variety of inputs that we have to consider in helping a client get the most out of its system always pushes us.

Each of our clients has different requirements, which is why we accentuate that we sell systems, not boxes. We conduct site surveys, understand logistical arrangements, and factor in building layout/space availability, patients and populations. Naturally, culinary traditions of each country, standards and food safety legislations come into play as well. We listen, question and probe, then develop, adapt and refine.

Keep in mind, too, that our responsibilities extend beyond simply providing a solution. There’s training and on-site implementation support as well as ongoing support through the life-cycle f the equipment.

All that work is validated when a customer is prepared to change or modernize their equipment after years of use. Customer retention is the greatest testament to the success of our relationships, and we have countless examples of that, wherever we operate.

Dealing with the pandemic

To look back at the past 18 months, the first thing we need to do is thank all healthcare and frontline workers for the way they’ve coped with this pandemic. We’ve seen first-hand some of the conditions and challenges they’ve gone through. It has been extremely hard for everyone but more so for them.

We can empathize with this situation as Bergamo, Italy, where our factories are located, was one of the Covid epicenters in Europe. Many of our colleagues got infected at the start of the pandemic and we decided to shut the factory to protect the rest of the workforce in advance of the national lockdown being announced. That gave us time to plan prior to the imposed lockdown and develop ways to continue operations so that we could support our customers. We quickly pivoted and prepared for a new way of remote working during lockdown.

“We’ve never worked

harder or been

busier. The way our

teams responded to

the situation was

unbelievable. The speed,

effort and creativity

during this time took

our company to an

entirely new level”

This also gave us sufficient warning for our offices in the UK, Germany, Canada, Holland, France

and the US to prepare to provide much needed client service. Despite the difficulties that so many clients were enduring, we were touched by those who took the time to thank us for supplying them with products and send thoughts of solidarity to healthcare facilities in Bergamo.

Adapt and overcome

During this time, we were told to stop and put tools down. Instead, we’ve never worked harder or been busier. The way our teams responded to the situation was unbelievable. The speed, effort and creativity during this time took our company to an entirely new level. The factory became a working lab. Feedback from hospitals indicated that staff were reluctant to work with meal trolleys due to concerns about cross-contamination, so we not only had to support clients, we also had to evolve our offerings.

Interestingly, this inspired an entirely new wave of product development, which was remarkable given the time span and challenging lockdown conditions. At the upcoming HostMilano show in October 2021 we’re preparing to launch two major new products which have a direct connection to client feedback during the pandemic.

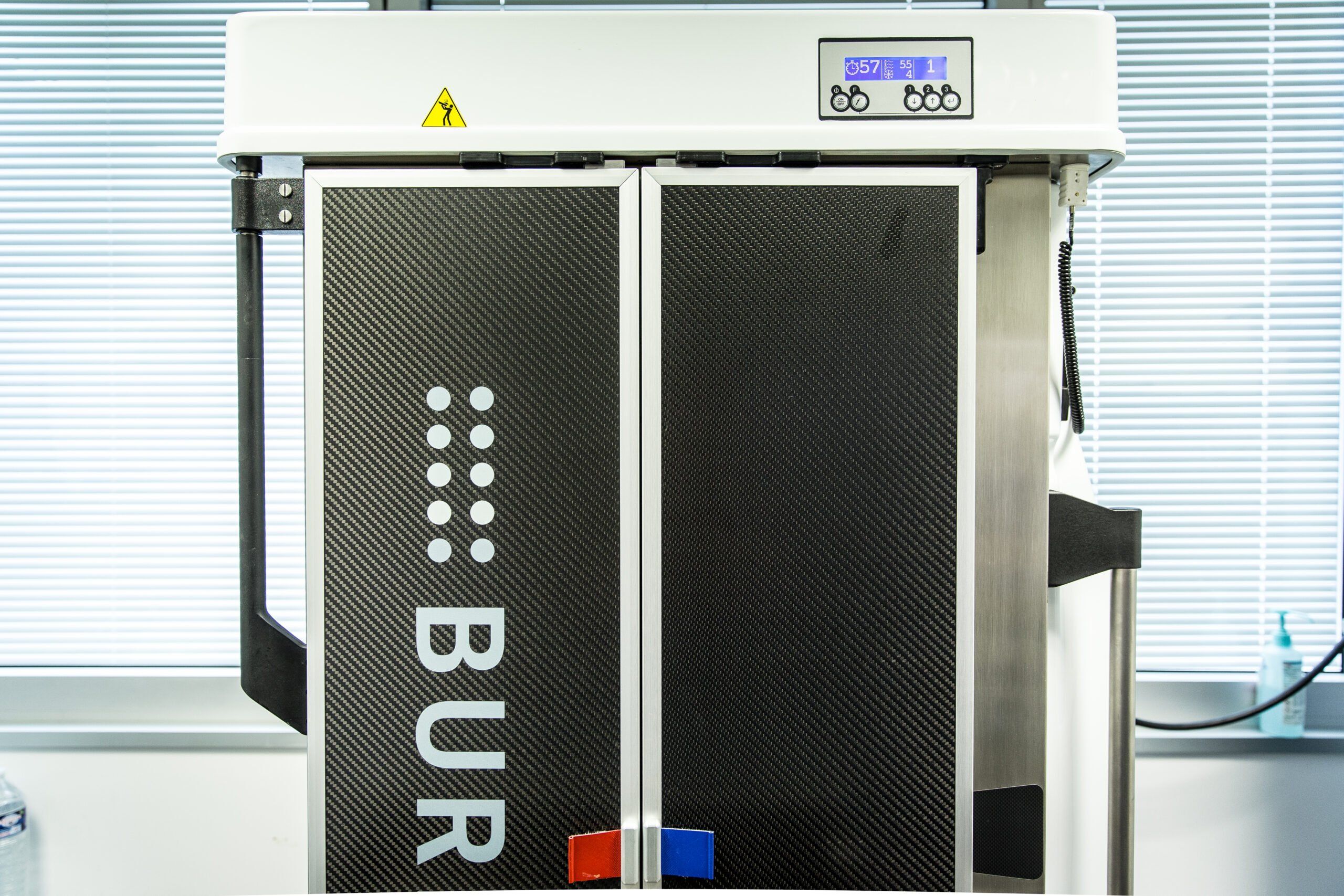

The first product is Logiko, which stands to be the greenest, lightest, easiest, cleanest and smartest tray meal delivery system available on the marketplace. Its product configuration and capacities will also open new market opportunities. We’ve constructed this piece in a new way that does not compromise the strength or durability of the equipment. We’ve reduced raw materials and plastics and introduced an operating system that reduces human input, increases productivity and diminishes the possibility of cross-contamination.

An app interface allows for touchless remote control, monitoring and programming of the trolley, and also provides HACCP data. What’s more, the touchpoints are all antimicrobial and this is the only trolley that can be 100% cleaned inside and out, even behind the ventilation panels. All in all, we consider Logiko a game-changer.

No less impressive is the development of what we’ve called the Steri-Station, a piece of equipment that completely sterilizes equipment inside and out. The fact that it can sterilize not just Burlodge equipment but all rolling stock to prevent cross contamination between departments and wards will appeal to healthcare managers everywhere.

Preparing for what’s next

As we look ahead to the next five years, we anticipate a huge demand on healthcare resources to manage this new reality. That includes coping with the demands of Covid, managing the backlog of procedures, and the possible long-term effects of reduced preventative care.

In response, we continue to develop products that allow operations to do more with less. Equipment like Logiko [pictured, above] is created expressly to maximize efficiencies, introduce greater automation, and allow for manageable running costs and greater flexibility all while boosting patient satisfaction.

This all comes back to our close relationships with clients, which starts with really understanding their day-to-day problems. The experience we have means we speak the same language and can respond with solutions that make a real difference.

Our HACCP monitoring system is a perfect example – a development that emerged directly from a client discussion. This system has now become industry standard and our BCloud is at the forefront of the technology. The same holds true for FeedBack, the digital patient satisfaction system that we’re currently developing. This device gauges patient and customer satisfaction by electronically generating feedback so hospitals can highlight and quickly respond to issues around food quality, temperature or presentation. It effectively provides a complete picture and closes the loop between BCloud HACCP equipment monitoring and patient feeding, which leads to improved patient satisfaction.

These efforts represent how Burlodge looks at the totality of service rather than focusing solely on a narrow area. It’s that thinking that continues to distinguish our approach and ambitions in the industry. We’re so much more than a company that just supplies food trolleys. By questioning how operations can run smoother, faster and better, we are far more invested in developing stronger relationships and generating creative solutions.

It’s a challenge that the entire Burlodge and temp-rite teams welcome every day and it’s why we look forward to finding ways to help clients better serve patients wherever in the world our equipment is found.